How to Boost Profit Margins in Construction Projects

Construction companies face shrinking profit margins as material costs rise 15% annually and labor shortages drive wages up 8% year-over-year.

Smart contractors know how to increase profit margin in construction through strategic cost management and operational efficiency. We at Devine Consulting have identified three core areas that consistently deliver measurable results for construction businesses.

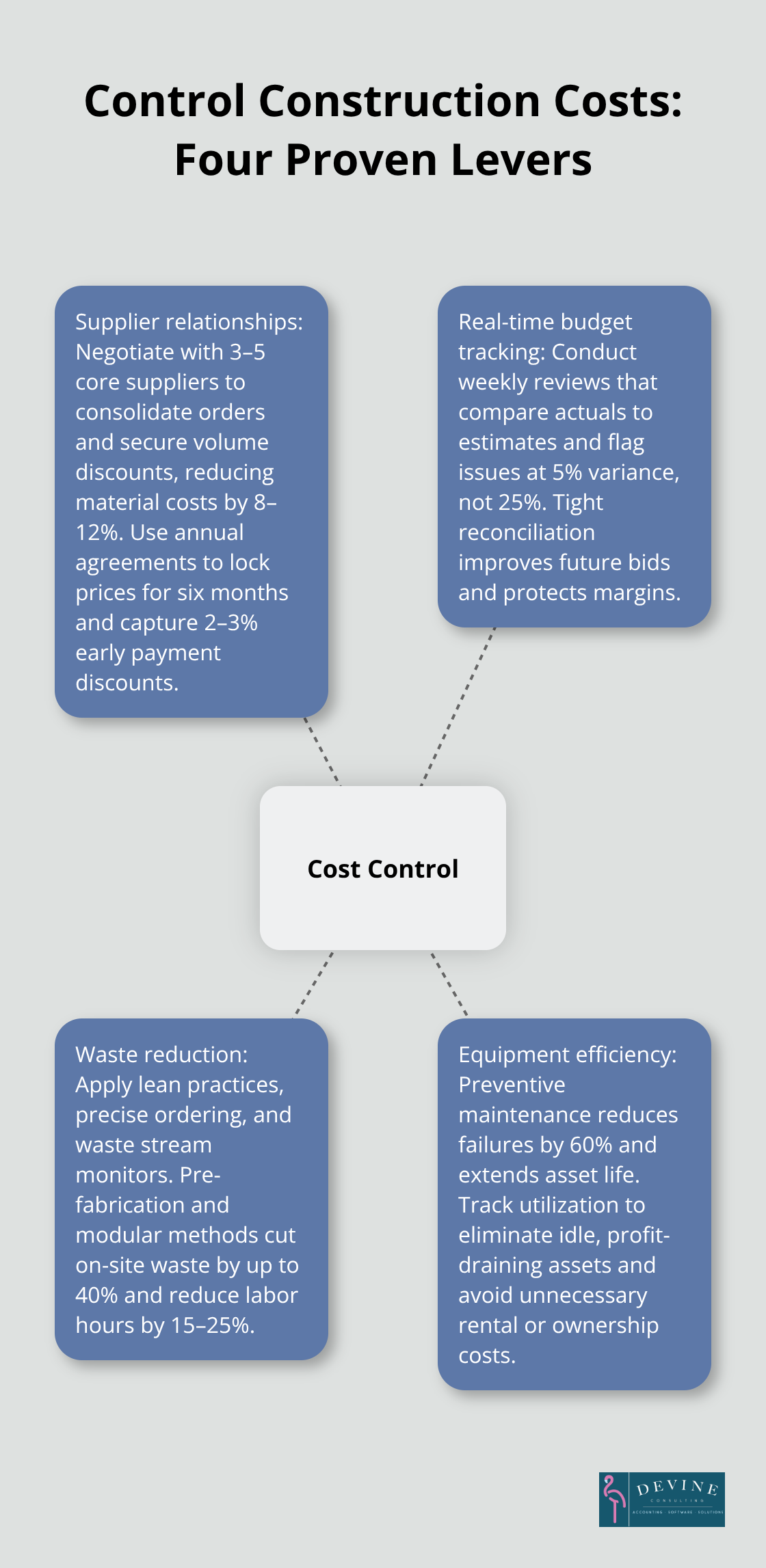

How Do You Control Construction Costs Effectively

Material costs represent 40-50% of total project expenses, making supplier relationships your most powerful profit lever. Construction companies that negotiate volume discounts with 3-5 core suppliers typically reduce material costs by 8-12% compared to project-by-project purchases. Successful contractors establish annual agreements that lock in material prices for six months while they secure 2-3% early payment discounts. The key lies in accurate demand forecasts and consolidated orders across multiple projects.

Master Real-Time Budget Tracking

Project budget failures cost contractors an average of 15-20% in profit margins according to Construction Financial Management Association data. Smart contractors implement weekly budget reviews with construction management software that tracks actual costs against estimates in real time. This approach catches cost overruns when they reach 5% variance, not 25%. Monthly budget reconciliation identifies patterns where estimates consistently miss the mark (allowing you to refine future bids and protect margins).

Eliminate Construction Waste Systematically

Construction waste directly eats into profit margins, with 76% of C&D waste being recovered or recycled in the U.S. Lean construction practices focus on precise material orders, standardized processes, and waste stream monitors. Contractors who track expenses meticulously reduce material waste by 20-30% within six months. Pre-fabrication and modular construction techniques cut on-site waste by up to 40% while they reduce labor hours by 15-25%.

Monitor Equipment and Tool Efficiency

Equipment downtime costs construction companies $50,000 per day on average projects. Preventive maintenance schedules reduce equipment failures by 60% and extend machinery life by 20-30%. Contractors who rent specialized equipment (rather than purchase) save 15-25% on capital costs while they access the latest technology. Track equipment utilization rates weekly to identify underused assets that drain profit margins through unnecessary rental or ownership costs.

Labor productivity improvements create the foundation for your next profit optimization strategy.

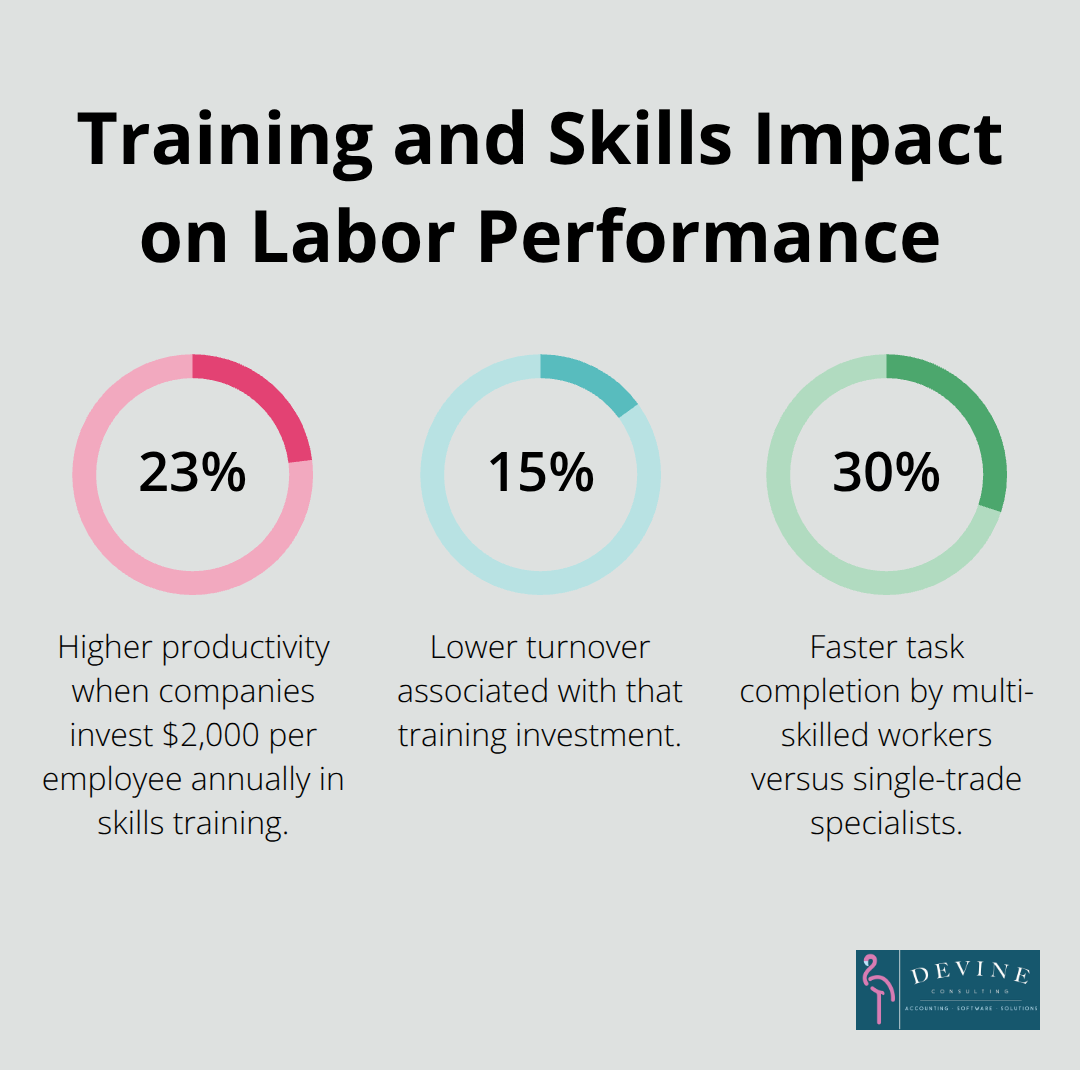

How Do You Maximize Labor Performance and Reduce Costs

Labor costs consume 25-35% of total project budgets, yet most contractors lose 20-40% of potential productivity through inefficient workforce management. Construction companies that invest $2,000 per employee in annual skills training see 23% higher productivity rates and 15% lower turnover according to Associated General Contractors data. Multi-skilled workers complete tasks 30% faster than single-trade specialists while they reduce project delays through elimination of wait times between specialized crews.

Smart contractors prioritize cross-training programs that develop electricians who handle basic plumbing and carpenters who manage simple electrical work.

Deploy Project Management Technology Strategically

Construction management software enhances project performance through improved measurement practices when contractors implement it correctly. Field reporting apps eliminate 3-4 hours of daily paperwork per crew while they provide real-time progress updates to project managers. GPS tracking on equipment and vehicles cuts fuel costs by 15% and prevents theft worth $1 billion annually across the industry. Contractors who use Building Information Modeling reduce errors, change orders and delays, improving project efficiency and delivering cost savings. Mobile time-tracking systems eliminate timesheet errors that typically inflate labor costs by 2-4% per project.

Schedule Resources for Maximum Efficiency

Poor scheduling wastes 15-25% of available labor hours through crew downtime and resource conflicts. Weekly resource allocation meetings prevent equipment bottlenecks that delay 40% of construction projects. Contractors who maintain 85% crew utilization rates (not 100%) achieve higher profit margins because they avoid overtime premiums and rushed work quality issues. Stagger trade sequences with 24-48 hour buffers between critical path activities to absorb unexpected delays without cascading project impacts.

Monitor Performance Metrics Daily

Track labor productivity rates against industry benchmarks to identify underperforming crews before they impact project timelines. Successful contractors measure output per labor hour and compare results across similar project types. This data reveals which teams need additional training or resource support (while highlighting top performers who deserve recognition and retention efforts).

Strategic financial planning builds on these operational improvements to protect and grow your profit margins.

How Do You Protect Cash Flow and Price Projects Profitably

Construction companies face significant financial challenges due to poor data management, with bad data causing $1.8 trillion in losses worldwide in 2020 and contributing to 14% of avoidable rework. Accurate job costing systems track actual expenses against budgets weekly, not monthly, which prevents cost overruns that destroy margins. Contractors who implement daily expense tracking can catch problem areas early and keep projects financially on track through effective budget variance monitoring.

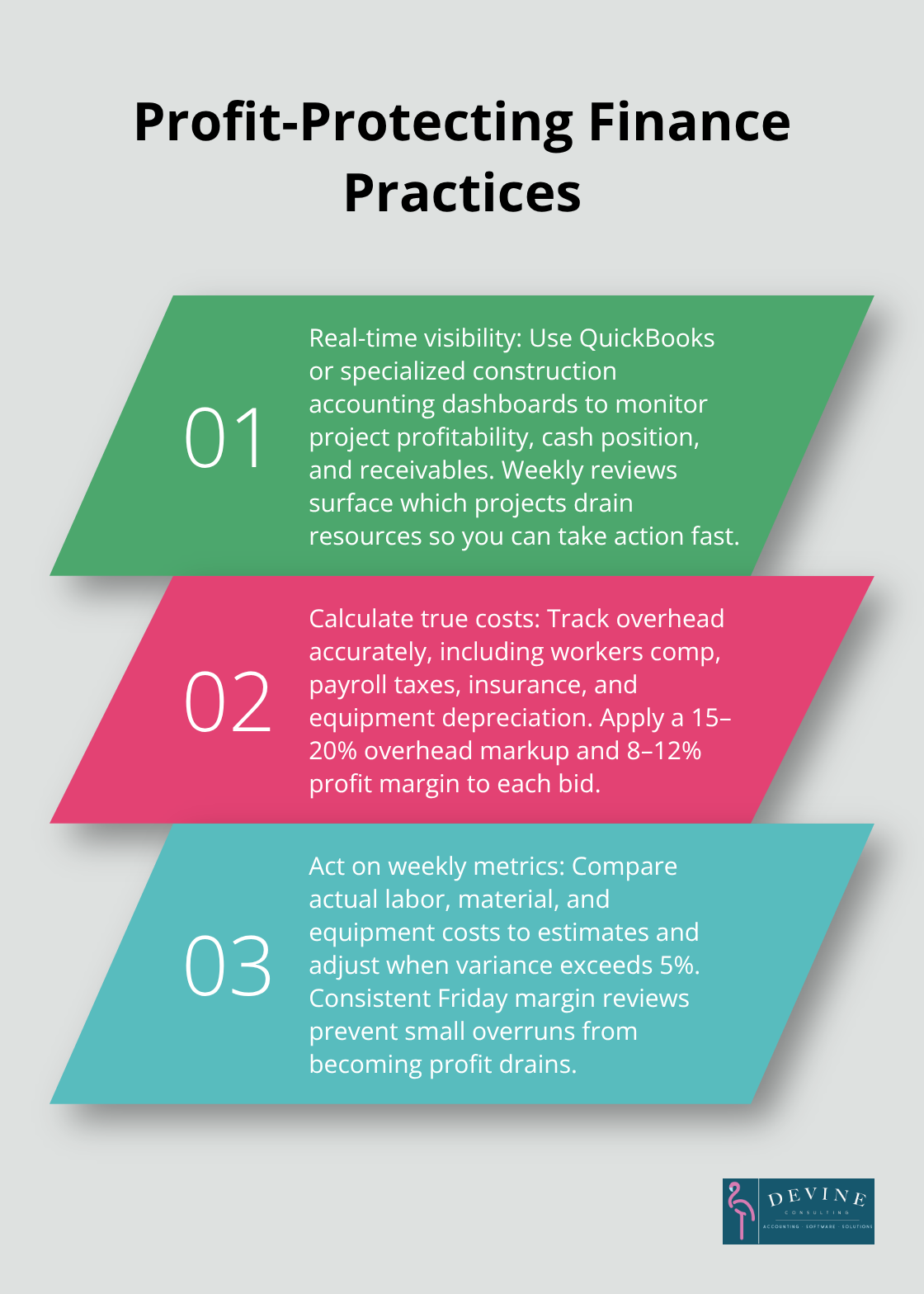

Track Financial Performance in Real Time

QuickBooks or specialized construction accounting software provides real-time financial dashboards that show project profitability, cash position, and outstanding receivables. Weekly financial reviews identify which projects drain resources and which generate sustainable profits. This approach allows contractors to make immediate corrections when projects start to drift from their financial targets.

Calculate True Project Costs Accurately

General contractors who track overhead costs accurately achieve 2.4% profit margins versus 1.4% for those who use outdated pricing methods (according to Construction Financial Management Association research). Calculate your true hourly burden rate including workers compensation, payroll taxes, insurance, and equipment depreciation. Add 15-20% markup for overhead costs and 8-12% for profit margins on each project bid.

Contractors who analyze completed projects find their actual costs exceed estimates by 12-18% when they fail to account for hidden expenses like permit delays, weather impacts, and change order processing time. Track every expense category for six months to establish accurate baseline costs for future bidding.

Monitor Weekly Performance Metrics

Projects that drift past break-even points rarely recover profitability. Weekly job cost reports compare actual labor hours, material usage, and equipment costs against original estimates. Successful contractors review project margins every Friday and make immediate adjustments when costs exceed 5% variance from budget.

This approach prevents small problems from becoming major profit drains. Monthly progress billing maintains steady cash flow while detailed expense tracking identifies which project phases generate the highest returns (for future business development focus).

Final Thoughts

Construction companies that master these profit optimization strategies consistently outperform competitors by 15-25% in net margins. The data shows clear patterns: contractors who implement systematic cost controls, invest in workforce productivity, and maintain rigorous financial oversight achieve sustainable growth while others struggle with razor-thin margins. Smart contractors understand that knowledge of how to increase profit margin in construction requires professional financial expertise that most lack internally.

We at Devine Consulting specialize in construction accounting solutions that transform financial chaos into strategic advantage. Our comprehensive approach includes accurate bookkeeping, real-time financial reporting, and strategic planning that allows construction businesses to focus on core operations while achieving financial stability. Companies with professional financial support make better bidding decisions, avoid costly cash flow crises, and position themselves for strategic growth opportunities.

Construction businesses that invest in proper financial management systems today build competitive advantages that compound over years (creating sustainable profit margins that weather industry volatility and economic downturns). These strategies transform from theory into measurable results for construction companies ready to optimize their financial performance. Professional accounting support delivers the expertise needed to implement these profit-boosting techniques effectively.